Are you ready to take your machining skills to the next level? Whether you’re an experienced CNC machinist or just starting out, having access to free CAD/CAM files can be a game-changer. With these digital blueprints, you can create complex parts with ease and precision – all without spending hours designing CNC Files Free them from scratch. In this blog post, we’ll explore what CAD/CAM is and how it works, the different types of CNC machines available, and where to find free CNC files online. So let’s dive in and start machining with confidence today!

What is CAD/CAM?

CAD/CAM stands for computer-aided design and computer-aided manufacturing. It’s a software that allows you to create digital models of parts or products using 3D modeling tools, and then generate machine codes that can be used by CNC Files Free Download machines to manufacture those parts.

CAD is the first part of this acronym and it focuses on creating the digital model. This involves designing the shape, dimensions, materials, and other attributes of a product in a virtual environment. CAD software has evolved significantly over time, becoming more intuitive and user-friendly with each iteration.

CAM comes next in CAD/CAM workflow which is where things get really exciting – CAM takes your model from being just an image on screen to something physical! This means taking your completed 3D model into production-ready data that will be read by CNC machines.

CAD/CAM technology has revolutionized modern manufacturing processes allowing machinists to do their jobs faster than ever before while also producing higher quality results.

Types of CNC Machines

There are many different types of CNC machines available for machining tasks, each with their own unique features and capabilities.

One common type is the milling machine, which uses rotating cutting tools to shape and cut materials into specific shapes or designs. These machines can range in size from small desktop models to large industrial-sized units.

Another popular type is the lathe machine, which rotates a workpiece while a cutting tool shapes it into a desired form. This type of machine is often used for precision turning operations on metal or wood materials.

Grinding machines are also commonly used for finishing operations on various materials such as metals and plastics. These machines use abrasive wheels or belts to remove material and create smooth surfaces.

There are also specialized CNC machines designed for specific tasks such as laser cutters, plasma cutters, water jet cutters, and more.

Choosing the right type of CNC machine depends on your specific needs and requirements for your project.

How to Use a CAD/CAM Program

Using a CAD/CAM program might seem intimidating at first, but with practice and patience, anyone can become proficient in it. The following are some tips on how to use a CAD/CAM program effectively.

It’s essential to have an understanding of the basic commands used in the software. This includes knowing how to draw lines, circles, arcs, and polygons. It’s also important to learn how to manipulate these shapes by rotating or scaling them.

Next, you need to be familiar with the CAM side of things – generating tool paths for your CNC machine based on your design files. Pay attention here as every cam software is different from another one.

It’s crucial to pay attention when setting up your project file before starting any design work. Establishing proper units (mm/inch), tolerances and orientation will help ensure that everything goes smoothly during machining later on

Additionally, it’s essential always to save your work regularly so that you don’t lose progress due power cuts or system crashes – trust us; this has happened too many times!

Take advantage of any online resources available such as tutorials videos and forums where other users can provide feedback on designs or answer questions about specific features within the software

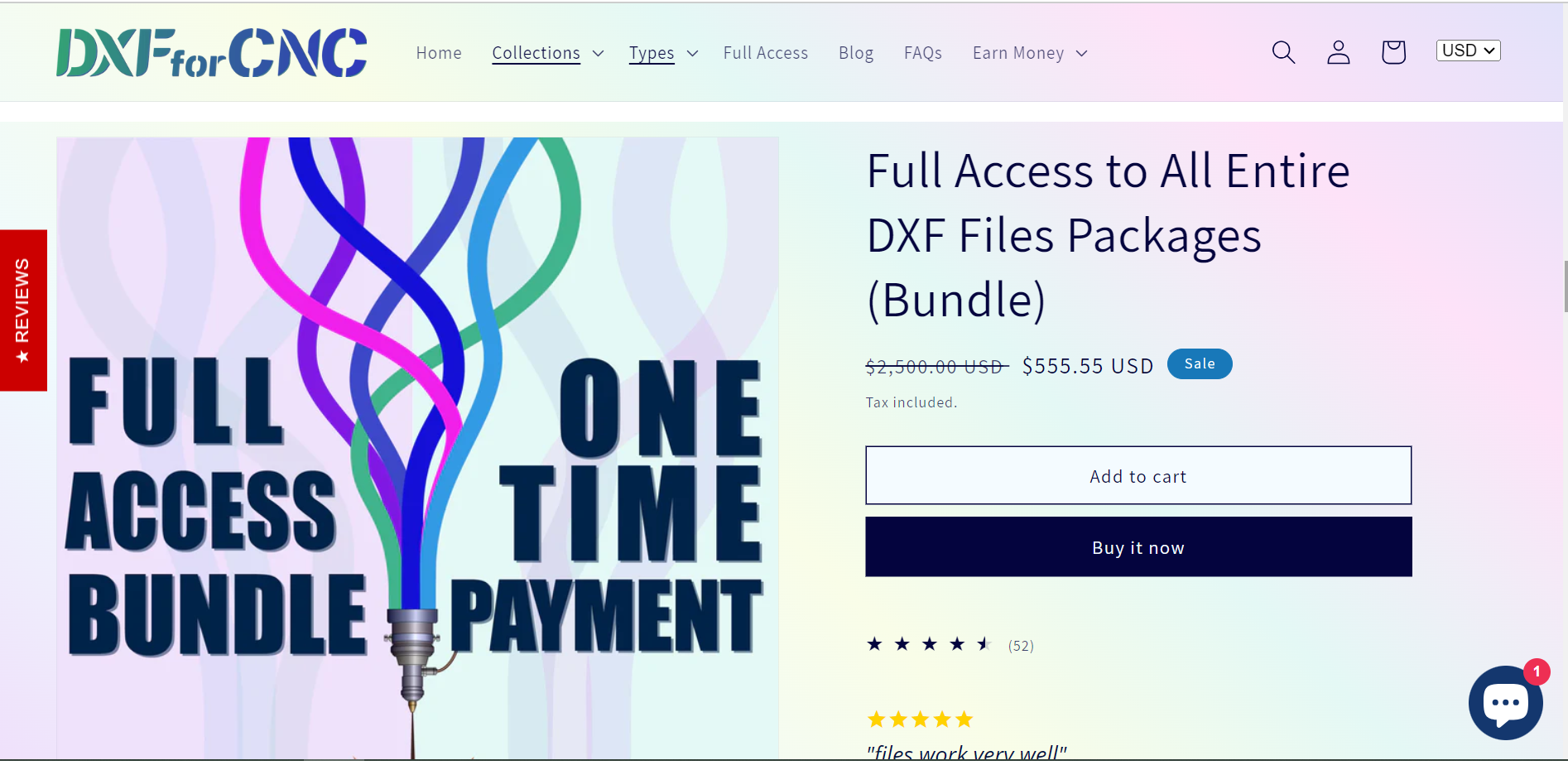

Free CNC Files for All

If you’re just starting out with CNC machining, it can be difficult to know where to begin. One of the best places to start is by finding free CNC files that you can use for practice and experimentation.

There are many websites available that offer free CNC files in a variety of formats, such as .

STL or .

DXF. These files range from simple shapes like squares and circles, to more intricate designs like gears and brackets.

Using these free CNC files allows you to get comfortable with your machine’s capabilities without having to design something from scratch. You’ll be able to see how different tool paths affect the final product, which will help you learn how to optimize your own designs later on.

It’s important to note that not all free CNC files are created equal – some may have errors or inaccuracies that could cause problems during machining. Always double-check dimensions and make sure everything looks correct before sending a file to your machine.

Using free CNC files is a great way for beginners (and even experienced machinists) to hone their skills and build confidence in their abilities.

How do I get started with CNC?

Getting started with CNC can seem daunting at first, but it doesn’t have to be. The first step is to choose the right machine for your needs and budget. There are many different types of CNC machines available, from small desktop models to large industrial machines.

Once you have your machine, the next step is to learn how to use a CAD/CAM program. This software allows you to create 2D or 3D designs that can be translated into G-code instructions for your CNC machine.

It’s important to start with simple projects as you’re learning how to use your new equipment. Begin by creating basic shapes and designs that allow you to get comfortable with the operation of the machine. As your skills progress, try more complex projects that challenge you.

Don’t forget about safety when working with any type of machinery – always wear proper protective gear such as goggles and gloves. Take time each day before using your machine for maintenance checks and cleaning.

Don’t be afraid to ask questions or seek out resources online or in-person for guidance on specific tasks or operations related to CNC machining. With practice and patience, anyone can become proficient in this exciting field!

What other tools and equipment do I need?

Aside from a CNC machine and CAD/CAM software, there are other tools and equipment that you’ll need to have on hand in order to start machining with confidence. One of the most important is cutting tools. These include drill bits, end mills, and router cutters, among others.

You’ll also need a variety of clamps and fixtures to hold your workpiece securely in place while it’s being machined. There are many different types available, including vise grips, C-clamps, and vacuum chucks.

A dust collector or shop vac is another essential tool for any CNC workshop. Machining generates a lot of debris and dust which can be harmful if not properly collected. A good dust collection system will help keep your workspace clean as well as protect your health.

Other useful equipment includes measuring tools such as micrometers and calipers for ensuring precise measurements; lubricants like oil or grease for maintaining your machine’s moving parts; safety gear like goggles or earplugs; and spare parts such as belts or bearings in case something breaks down.

By having these additional tools at your disposal along with your CNC machine, you can ensure that you’re fully prepared to take on any project with confidence!

How often should I tune my CNC machine?

Maintaining your CNC machine is essential to keep it in good working condition. Regular tuning helps ensure precision, accuracy and quality of the final product. But how often should you tune your CNC machine? The answer depends on various factors.

The frequency of tuning largely depends on how frequently you use your machine. If you are using it for long hours or continuously throughout the day, then regular maintenance and tuning is required. On the other hand, if it’s not used very often, then occasional maintenance will suffice.

The type of material being machined also plays a crucial role in determining when to tune your CNC machine. Harder materials like metals require more frequent tuning as compared to softer ones like plastics or wood.

Environmental factors such as temperature and humidity levels can also affect your CNC machine’s performance. It’s important to maintain a stable environment around the machine to avoid any sudden changes that could negatively impact its performance.

Keeping track of any wear and tear on parts like bearings or belts can help determine when they need replacement which may require additional adjustments during routine maintenance.

There isn’t any hard-and-fast rule regarding how often one should tune their CNC machines; however regularly monitoring its performance would help identify where improvements are needed before issues escalate into major problems causing downtime and affecting production output.

Conclusion

CNC machining is an exciting and rewarding process that can be easily accessible to anyone with the right tools and knowledge. With the availability of free CNC files online, it has never been easier to get started in this field. By understanding CAD/CAM programs and choosing the right type of machine for your needs, you can create stunning designs and products with ease. Remember to always take care of your equipment by tuning it regularly and investing in quality tools.

So why not start machining with confidence today? With a little practice, patience, and creativity, you could become a master CNC machinist in no time!